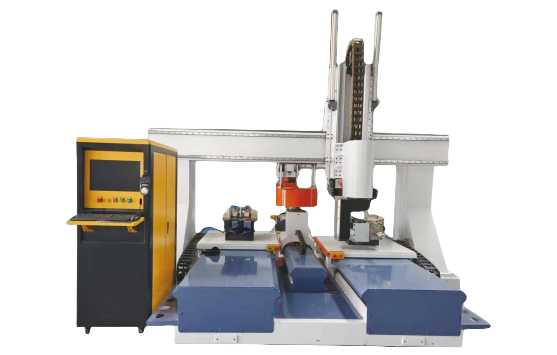

Optimizing cross-cut machine

Application:

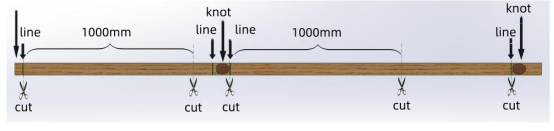

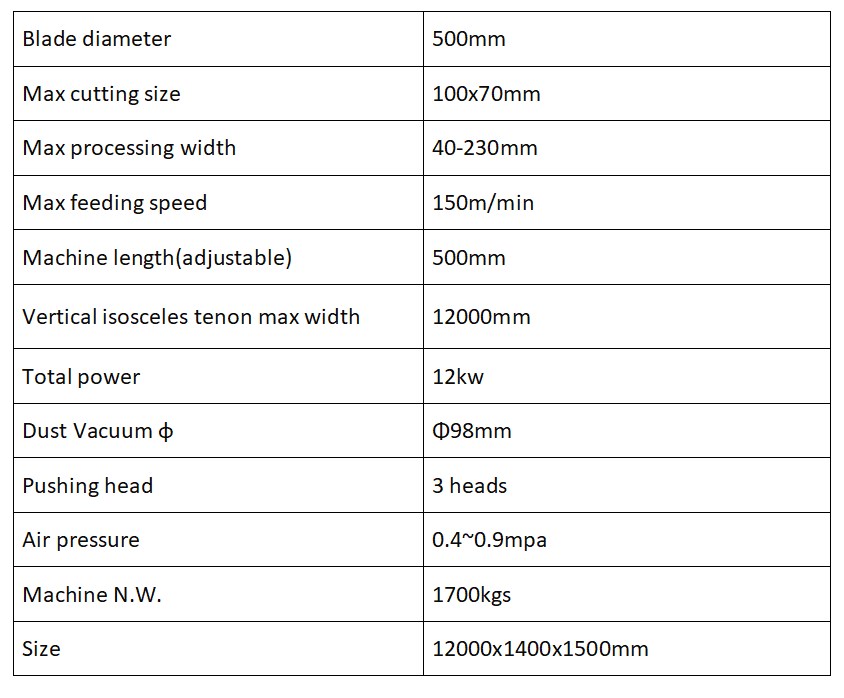

Optimizing cross-cut saws offer high-speed and high-precision trimming of wood components, helping manufacturers remove defects from workpieces and optimize usable lengths. Built with a high-rigidity frame structure refined through stress analysis and stabilization treatment, they ensure long-term structural accuracy and resistance to deformation. Bottom-feed roller systems provide smooth feeding and precise positioning, even when handling bent or twisted wood. Spindles and feed rollers operate with synchronized toothed belts, minimizing power loss while maintaining precise transmission. Pneumatic control systems and actuators from world-class brands deliver reliable high-speed performance and long-term operational stability.

Advantage:

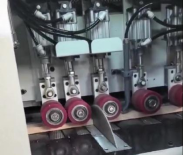

1.The main engine adopts the lower active pressure roller rolling feeding, which ensures smooth feeding and accurate positioning even for bent or twisted wood.

2.Pneumatic control and actuators are from the world’s top brands, with good reliability and high-speed motion stability.

3.The main shaft and feeding roller are driven by synchronous toothed belts, which have low power loss and high transmission accuracy.