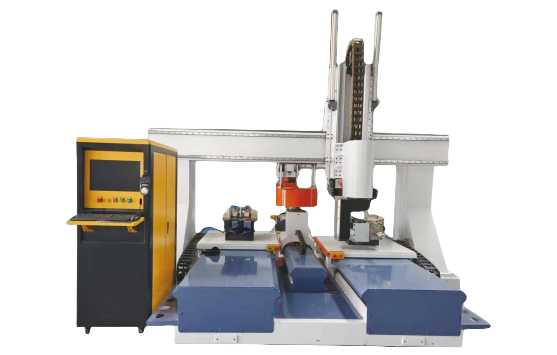

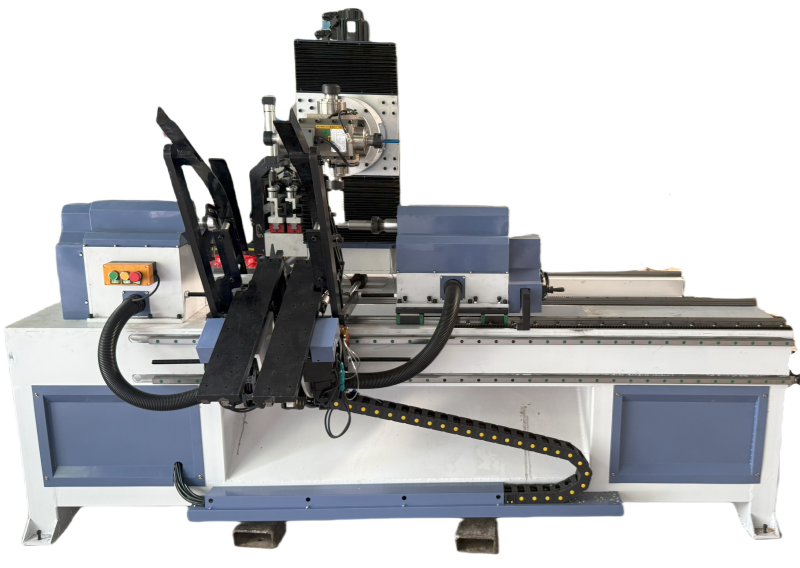

CNC 5-axis Lathe

Application:

5-axis CNC wood lathes combine turning, milling, engraving, drilling, and sawing into a single system for solid wood components. With interpolated movement across the X, Y, Z linear axes and two rotary axes, these woodworking systems enable precise machining of curved surfaces and complex shapes in one setup. This design boosts production efficiency while ensuring high-quality finishes, even for intricate workpieces. Designed to handle multi-dimensional surfaces, 5-axis CNC work centers allow the creation of unique designs and complex components that would be challenging with standard systems. Ideal for crafting artistic details and structural elements, they provide the flexibility and precision required for advanced woodworking production.

Advantage:

1.The synchronized movement across five axes handles curved and rotating surfaces with precision, completing complex multi-surface machining in a single setup.

2.A modular hardware platform ensures accurate positioning of each workpiece, providing reliable and consistent results even with intricate designs.

3.Supports machining of flat surfaces, curves, inclined planes, angled holes, 2D and 3D surfaces, and three-dimensional contours.

4.Offers single clamping, precise positioning, and simultaneous five-axis operations including milling, engraving, drilling, and sawing. This enables efficient multi-directional machining in a single workflow, enhancing both productivity and quality for woodworking applications.