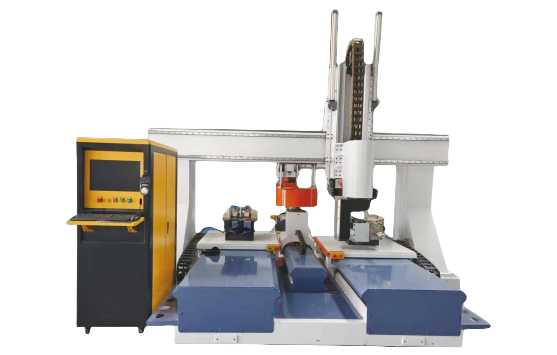

Auto Feeding Woodworking Cutting Machine

Woodworking machinery cutting machine is the core equipment of modern wood processing, which is dedicated to efficient and accurate completion of board cutting, blanking and special-shaped parts processing. Its core function is to drive through the CNC system (CNC), combined with high-hardness alloy tools or laser cutting heads, to quickly divide raw materials such as wood and artificial boards into the required shape and size according to the preset drawings.

Main types and advantages:

CNC cutting machine: suitable for mass production of customized furniture, wooden doors, etc., intelligently optimize the layout path through CAD/CAM software, and the material utilization rate is as high as more than 95%.

Gantry cutting machine: equipped with servo motor and linear guide rail, the cutting accuracy can reach ±0.1mm, and it supports complex curve processing.

Multi-process integrated machine: integrated cutting, punching, slotting and other functions, with automatic tool changing system, a single device can complete the whole process processing.

Technical highlights:

Intelligent deviation correction: Laser scanning automatically identifies the edge of the board to avoid burrs or defective areas;

Cloud interconnection: Real-time monitoring of equipment status, remote update of processing programs, and adaptation to flexible production needs;

Safe and efficient: Equipped with vacuum adsorption table and dust removal system to ensure the stability of high-speed cutting (≥20 meters/minute) and clean working environment.

Application scenarios:

Widely used in customized furniture, decorative building materials, musical instrument manufacturing and other fields, especially suitable for small batch and multi-variety flexible production mode, to promote cost reduction and efficiency improvement of traditional wood industry through intelligent upgrading.